This user-friendly control supports the user during setup, with creating programmes and by predicting potential programme errors. FANUC control for shorter machining timesīy using a FANUC control DMG MORI has managed to considerably reduce the throughput times of the NHX 6300 2 nd Generation.

#DMG MORI NHX MANUAL#

Over 99 percent of the sludge is removed in this way, which reduces manual cleaning to a minimum, significantly reduces wear of the coolant pump and increases the useful life of the coolant and therefore also the service life of the tools. This is then led into the 1,200 l coolant tank where a nozzle agitates the fluid and filters out the impurities. A filter collects the sludge while the chips are being removed. Coolant cleaning in the standard versionĪs the fine chips produced in particular in the machining of cast parts give rise to a high volume of sludge, DMG MORI has combined chip removal with a cleaning system for the coolant. The same applies to the optional coolant temperature control with which DMG MORI achieves a high level of thermal stability. Just like the stability and powerful spindles, the direct measuring system from MAGNESCALE also contributes to the higher precision of the NHX 6300 2 nd Generation. A third version from the powerMASTER range with 16,000 rpm is geared towards customers who need higher speeds for even better surface finishes. A powerMASTER spindle with up to 1,413 Nm is also available for demanding heavy-duty machining. powerMASTER for every applicationĮven in its standard version the NHX 6300 2 nd Generation is equipped with a powerMASTER spindle with a speed of 12,000 rpm and 807 Nm torque. DMG Mori was establish in 2010 with the merger of the Japanese company Mori Seiki, and the German company Gildemeister AG. One machine, surplus, or an entire plant. is a Japanese company located in Nagoya, Japan, and is one of the largest machine tool builders in the world. Name Company City / State Country Email Phone How can we help you Sell Your Machines. Applications and Parts Highlights Machine and Technology Others Machine Specifications Expert on Machining of Large and Difficult-to-cut Workpieces The NHX. Request A Quote Indicates required questions. Up to eight machines can be linked with this system, offering space for maximum 99 pallets, which are directed to up to five setup stations. DMG Mori NHX 4000 DMG Mori NHX5000 DMG Mori NHX-5000 DMG Mori NHX 5000 DMG Mori NHX6300 DMG Mori NHX-6300 DMG Mori NHX 6300. In addition the NHX 6300 2 nd Generation can also be connected to a linear pallet pool (LPP). A setup station enables preparation of the next job parallel to primary machining.

Optional magazine solutions are designed for up to 330 tools. The wheel magazine with space for 60 tools ensures high productivity and at the same time shorter setup times. The NC rotary table is designed for pallets up to 630 x 630 mm, the workpiece height is 1,300 mm, and max. The horizontal machining centre achieves a rapid traverse of 60 m/min on travel paths of 1,050 x 900 x 1,030 mm (X/Y/Z). The design of the machine bed and base has been given an even more stable construction than the predecessor model and roller guides have been installed for all axes. Take a look at our selection of DMG-Mori Used Machines we have in inventory and can service for you.“With its enormous stability and high cutting performance the NHX 6300 2 nd Generation excels in the machining of cast components”, says Mitsuru Taga, General Manager Horizontal Machining Center in Iga, about the world premiere from DMG MORI. If you’re looking to purchase a DMG Mori machine, we have one of the largest inventories of manufacturing equipment in the US, including CNC Lathes, CNC Machining Centers, CNC Lasers, CNC Boring Mills, CNC Grinders, Turret Punches, Coordinate Measuring Machines, Electrical Discharge Machines, Press Brakes, CNC Gun Drills, Bridge and Gantry Mill Options, Rotary Tables and a variety of gear equipment. Used DMG-Mori Inventory on Tramar Industries DMG Mori Seiki is a manufacturer of machine tools, peripherals and systems with more than 160,000 installations around the world. Exclusive Tech Tour in Hoffman Estates, IL. CLX 450 TC: Future-proof entry in 6-sided complete machining.

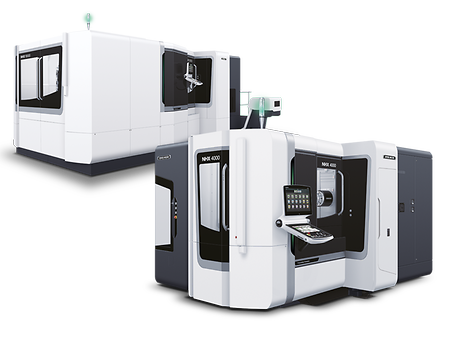

DMG Mori Seiki, formerly known as Mori Seiki, was founded in 1948 and since then has grown into one of the largest machine tool builders in the world. DMG MORI USA - CNC machine tools for all cutting machining applications. With the NHX 4000 2nd Generation and NHX 5000 2nd Generation, DMG MORI presents compact and dynamic general-purpose horizontal machining centers enabling.

0 kommentar(er)

0 kommentar(er)